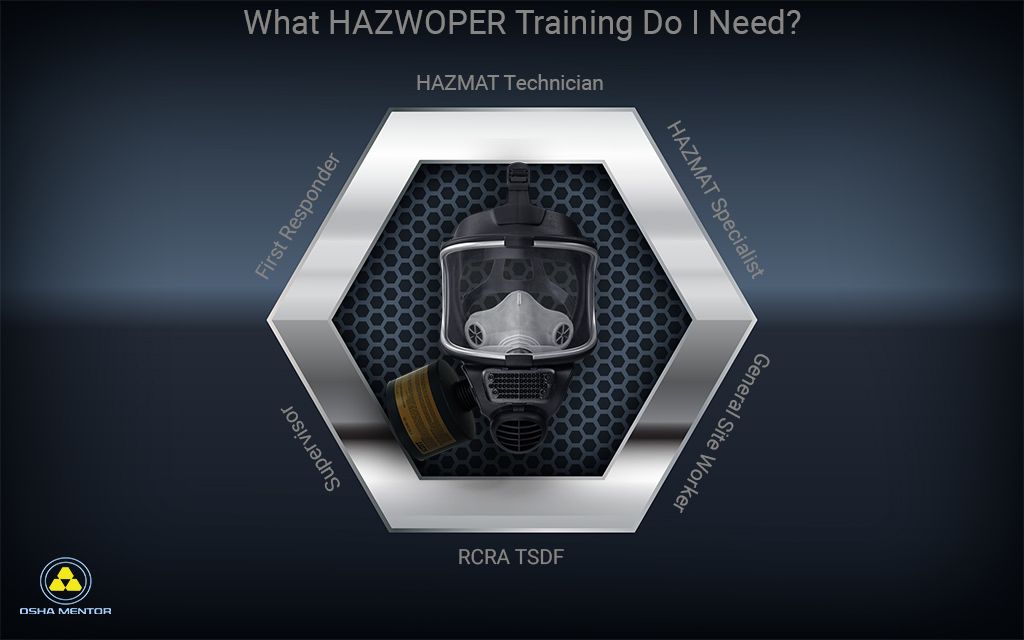

What HAZWOPER Training Do I Need?

If you are new to this field, you will discover there are many acronyms. HAZWOPER is an acronym defined as Hazardous Waste Operations and Emergency Response. Per the Occupational Safety and Health Administration (OSHA) regulations, HAZWOPER training is required for workers who perform cleanup, emergency response or corrective actions involving the uncontrolled release of hazardous substances. There are differing responsibilities for this work and thus many different job titles/descriptions. Workers must be trained commensurate with their job responsibilities. Accordingly, OSHA has listed in 29 Code of Federal Regulations (CFR) Part 1910.120 job titles/descriptions and the required training for each discipline. The employer has the responsibility of ensuring a safe work environment for their workers and/or employees.

Three Levels of HAZWOPER

Before we discuss the job classifications, let’s take a look at the 3 levels of HAZWOPER and where they apply along with the regulatory citation.

1. Cleanup operations required by a governmental body, (federal, state, local) involving hazardous substances encountered at uncontrolled hazardous waste sites. - 29 CFR 1910.120 (e).

2. Operations involving hazardous waste conducted at Treatment, Storage, and Disposal Facilities (TSDF) regulated by the Resource Conservation and Recovery Act (RCRA). This includes any corrective actions - 29 CFR 1910.120 (p).

3. Emergency response operations involving releases of, or substantial threats of releases of, hazardous substances without regard to location - 29 CFR 1910.120 (q).

HAZWOPER Job Titles/Classifications

Cleanup Operations - 29 CFR 1910.120 (e)

General Site Worker

General Site Worker

Employees who will work at a contaminated site and be exposed to hazardous substances at or above their respective Permissible Exposure Limit (PEL), must receive General Site Worker training. This initial training must be conducted offsite and is typically known as HAZWOPER 40 or 40 Hour HAZWOPER. This training is very comprehensive with the minimum training time set at 40 hours along with 3 days of actual field experience. The actual field experience must be conducted by a trained supervisor. The OSHA HAZWOPER 40 hour time requirement is often just a minimum as hands-on training on PPE or equipment used is required. The hands-on training must be with the actual PPE or equipment a person will use in their job. In our discussion’s with OSHA regulators, this is their expectation and requirement - training with the actual equipment an employee will use in their job.

Temporary Site Worker

Personnel who will visit a contaminated site or have short duration work tasks must complete a minimum of 24 hours of initial training (commonly known as either 24 Hour HAZWOPER or HAZWOPER 24). This initial training must be conducted offsite. An employee must also complete 1 day of actual field experience. The field experience must be conducted by a trained and experienced supervisor. These individuals cannot be exposed to hazardous substances at or above the PELs. Examples of short duration work tasks include conducting geophysical surveys, retrieving groundwater samples, or visiting a site.

Supervisor

Supervisor’s must have the initial General Site Worker training (including the three days of actual field experience) prior to taking a supervisor course. The HAZWOPER Supervisor course must be a minimum of 8 hours in duration and cover specialized topics.

Refresher Training

Annual refresher training is required for the cleanup operation levels as listed above. The training requirements vary based on the job title/description. However, the refresher training must be at least 8 hours in duration.

Emergency Response - 29 CFR 1910.120 (q)

First Responder Awareness (FRA) Level

This level of training is for employees that are responsible for discovering and/or identifying the unintentional release of hazardous substances. This training will need to cover important topics such as understanding and identifying what hazardous substances are, the risks associated with them, and which authorities/personnel to notify upon discovery of a release. This level of training does not extend past identification of hazardous substances. Employees with this level of training only notify emergency responders of hazardous substances releases and do not take any further action.

First Responder Operations (FRO) Level

Personnel trained at this level are involved in an initial response for the purpose of protecting people, property and the environment from releases of hazardous substances. The FRO are trained to respond defensively, instead of actually trying to stop the release at the source. These professionals will have knowledge of basic hazard and risk assessment techniques.

The training will include the following topics.

The training will include the following topics.

• Ability to select (don and doff) and use the proper Personal Protective Equipment (PPE).

• Understand and identify basic hazardous material/substances terms.

• Ability to manage, control, contain and/or confine hazardous substances releases.

• Ability to implement basic decontamination procedures.

• Know relevant standard operations procedures and termination procedures and how to implement them.

Hazardous Material (HAZMAT) Technician

Professionals with this level of training can offensively respond to hazardous substances releases and attempt to terminate them. Employees trained at this level understand their specific role in limiting the spread of further contamination. They will know and follow the chain of command when it comes to emergency responses, and have knowledge for the different decontamination procedures for the hazardous substances releases.

Additionally, employees with this type of training are competent in industrial chemical terminology. They understand the basic chemical reactions and the need to segregate certain chemicals. They also receive training on the use of proper PPE and the equipment’s limitations. The minimum training time for this level is 24 hours. But this is just a minimum as site-specific training must be conducted for any PPE or equipment an employee will use.

Additionally, employees with this type of training are competent in industrial chemical terminology. They understand the basic chemical reactions and the need to segregate certain chemicals. They also receive training on the use of proper PPE and the equipment’s limitations. The minimum training time for this level is 24 hours. But this is just a minimum as site-specific training must be conducted for any PPE or equipment an employee will use.

Hazardous Material (HAZMAT) Specialist

The primary difference between this level and the HAZMAT Technician is that more emphasis is placed on understanding the field of industrial chemistry and the latest remedial technologies. They are considered very knowledgeable in these two areas. These professionals will aid and support HAZMAT Technician’s should the need arise for a more specialized response to a release. Personnel trained to this level will complete the same level of training as a HAZMAT Technician but will specialize in the two areas mentioned above. A person must have technician level competency plus specialized knowledge.

On scene Incident Commander

The On scene Incident Commander has responsibility for the entire emergency response effort. If the Incident Commander is a employed by a private company, this person will interface with government officials. The level of training is to equip a person with the knowledge to assume complete control of an unintended hazardous substance release or emergency. Typically, they will have advanced knowledge of chemicals, emergency plans, site controls, etc,. They will understand the hazards and risks associated with employees wearing PPE. In short, incident commanders are responsible for protecting everyone on site and remediating the contamination from a hazardous substance release. To become an Incident Commander, the minimum training time is 24 hours plus competency in several areas.

Refresher Training

Annual refresher training is required for the emergency response levels as listed above. The training requirements vary based on the job title/description. Depending upon an employee’s role or job, the training has minimum hour requirements or competency requirements.

RCRA TSDF Operations - 29 CFR 1910.120 (p)

Employees who fall under this level must receive a minimum of 24 hours of initial training. The training will address specific health and safety topics related to RCRA TSDF operations.

Refresher Training

An 8 hour annual refresher is required in order to maintain certification.

Related Articles

OSHA Certification

HAZWOPER PPE Levels

What HAZWOPER Training Do I Need?

HAZWOPER Training Regulations

What Is OSHA HAZWOPER?

HAZWOPER PPE Levels

What HAZWOPER Training Do I Need?

HAZWOPER Training Regulations

What Is OSHA HAZWOPER?

Sources

U.S. Occupational Safety and Health Administration

Write your awesome label here.